Loading Process for Molecular Sieve 13X and Activated Alumina

2023-07-14

Loading Process for Molecular Sieve 13X and Activated Alumina 23-7-14

In various industries, molecular sieve 13X and activated alumina are widely used as adsorbents due to their exceptional properties. These materials play a crucial role in processes such as gas drying, purification, and separation. Understanding the loading process for molecular sieve 13X and activated alumina is essential for optimizing their performance and ensuring efficient operations. In this article, we will delve into the loading process for these two adsorbents, exploring key, techniques, and best practices.

Molecular Sieve 13X Loading Process: Molecular sieve 13X is a highly effective desiccant known for its ability to selectively adsorb water molecules from gases and liquids. The loading process for molecular sieve 13X involves several steps:

1、Preconditioning: Before loading, it is crucial to precondition the molecular sieve to remove any moisture or contaminants. This can be achieved by heating the material at a specific temperature for a defined period.

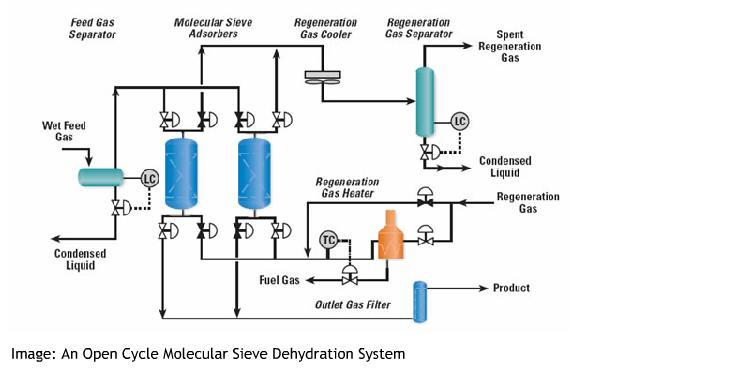

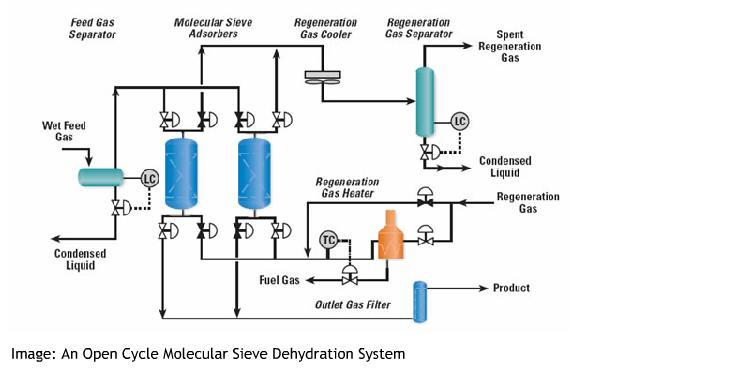

2、Selection of Loading Method: There are different methods for loading molecular sieve 13X, including pressure swing adsorption (PSA), vacuum swing adsorption (VSA), and temperature swing adsorption (TSA). The choice of method depends on factors such as the desired purity level, flow rate, and specific application requirements.

3、Loading Procedure: The molecular sieve 13X is typically loaded into a vessel or column designed for adsorption processes. The material is carefully introduced into the system, ensuring uniform distribution and avoiding any compaction or channeling that may hinder its performance.

4、Activation: Once loaded, the molecular sieve 13X may require activation to remove any residual moisture absorbed during the loading process. This step is crucial to restore the adsorbent's full capacity and efficiency.

Activated Alumina Loading Process: Activated alumina is a versatile adsorbent used for the removal of various impurities, including moisture, fluoride, and volatile organic compounds. The loading process for activated alumina involves the following steps:

1、Preconditioning: Similar to molecular sieve 13X, activated alumina also requires preconditioning to eliminate any moisture or contaminants. This can be achieved by heating the material at a specific temperature for a defined period.

2、Selection of Loading Method: The loading method for activated alumina depends on the specific application and system requirements. Common methods include gravity loading, pneumatic loading, and mechanical loading.

3、Loading Procedure: Activated alumina is loaded into a vessel or column designed for adsorption processes. Care should be taken to ensure even distribution and avoid compaction or channeling that may compromise its performance.

4、Activation: After loading, activated alumina may require activation to remove any residual moisture absorbed during the loading process. Activation typically involves heating the material to a specific temperature to restore its full adsorption capacity.

Best Practices for Loading Molecular Sieve 13X and Activated Alumina:

Follow manufacturer guidelines: Always refer to the manufacturer's instructions and recommendations for loading procedures, as they may provide specific guidance based on the product's characteristics.

Proper handling and storage: Handle molecular sieve 13X and activated alumina with care to prevent contamination or damage. Store them in a dry environment to maintain their effectiveness.

Quality control: Regularly monitor the loading process and conduct quality control checks to ensure proper distribution, absence of channeling, and optimal performance.

Safety precautions: Adhere to safety protocols when working with these adsorbents, including wearing appropriate personal protective equipment (PPE) and following relevant safety guidelines.

Conclusion:

The loading process for molecular sieve 13X and activated alumina is a critical step in maximizing their adsorption capabilities. By understanding the key considerations, techniques, and best practices outlined in this article, writers can provide valuable insights to readers involved in industries that rely on these adsorbents. Proper loading procedures ensure efficient operations, improved product quality, and enhanced overall performance.